Ultramid® Ccycled®

Ultramid® Ccycled® is an innovative, mass-balanced polyamide (100%, PA6) that we at pinqponq have been using for the outer fabric of our SOLID products since summer 2023. Through an innovative chemical recycling process, the use of Ultramid® Ccycled® enables us to reduce the use of fossil raw materials at the beginning of the value chain, give used tyres a second life and thus make (one out of many still needed) important contributions to promoting a circular economy for waste that was previously difficult to recycle.

All Solid Styles

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

Recycling & Manufacturing Process

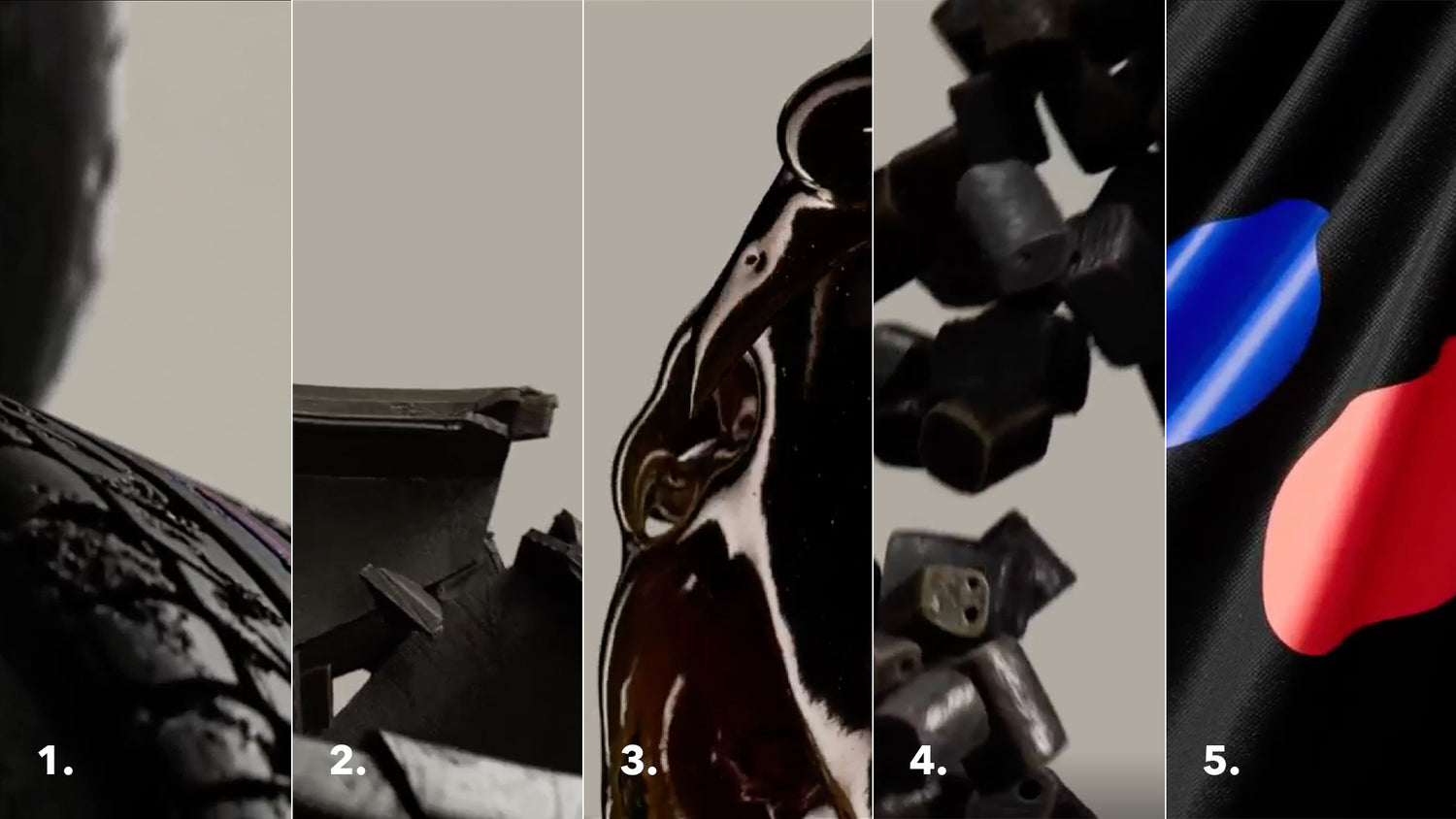

Used tires are collected and delivered to recycling companies (1)

Shredding of used tyres (2)

Chemical recycling (pyrolysis) of the used tire rubber into recycled material, called pyrolysis oil (3)

The granules are spun into yarns and woven into the outer fabric for our SOLID products (4)

Mass-balanced fabric made from Ultramid® Ccycled® (5)

Chemical recycling - One of many contributions to building a circular economy for difficult-to-recycle plastic waste and used tyres

The ideal image of a functioning circular economy describes an economic system that aims to reduce resource consumption, waste production and environmental pollution. Through processes such as reuse, repair, remanufacturing, recycling or composting, products and materials can be kept in the material cycle permanently and with high quality.1 Currently, however, far too few products and materials are recycled at the end of their use and kept in the material cycle as so-called secondary raw materials. The majority ends up as waste in landfill sites or is incinerated to generate energy. In addition to Design for Circularity, the fundamental minimisation of raw material consumption and extending the use of products, it is therefore important to further exploit the potential for additional recycling through innovative technologies in order to close the loop.23

Ultramid® Ccycled® is a result of BASF's ChemCycling® project, in which the company and its technology partners are focussing on pyrolysis technology. The main aim is to find a solution to the fact that some types of waste, such as mixed, contaminated plastic waste or used tyres, are currently difficult to recycle or cannot be mechanically recycled for technological, economic or ecological reasons. While sorted, single-stream waste should be recycled mechanically, chemical recycling is an important addition for challenging waste streams in order to increase recycling rates and promote the development of a functioning circular economy.

A highly efficient thermochemical recycling process, known as pyrolysis, is used to extract a recycled raw material, pyrolysis oil, from used tyres, which is then fed into BASF's polyamide production. This saves fossil raw materials at the beginning of the value chain. Using an independently certified mass balance approach, the proportion of recycled raw material can be allocated to the Ultramid® Ccycled® material that we use in the outer fabrics of our SOLID products.

What exactly is the mass balance approach or a mass-balanced product?

Up to now, chemical chemical primary products for the production of conventional textile fibres, such as polyamide, have been made from fossil raw materials such as natural gas and crude oil. If these primary products are to be produced in a more resource-efficient way, they must be replaced by renewable or recycled raw materials, such as pyrolysis oil. As production takes place in huge, complex production networks, it makes neither economic nor ecological sense to set up a separate production infrastructure that exclusively utilises such alternative raw materials. Instead, the solution is to gradually feed recycled raw materials into the existing production chain alongside fossil raw materials. The end products, such as polyamide, remain chemically unchanged. The mass balance approach is the method that ensures that the proportion of recycled raw material (pyrolysis oil) can be attributed to the end product (Ultramid® Ccycled®).

In detail: Our suppliers buy the mass-balanced Ultramid® Ccycled® from BASF. BASF buys the pyrolysis oil from chemically recycled car tyres and feeds it into the production chain. The alternative raw material is mixed with the fossil raw material in the numerous value chains of the interlinked production network. The independently certified mass balance approach, however, makes it possible to allocate the proportion of pyrolysis oil to Ultramid® Ccycled®, even if the recycled raw material is not physically contained 1:1 in the final material. In this way, BASF can gradually increase the proportion of resource-conserving raw materials in the production of chemical primary products as demand increases and use existing production facilities. The principle works in a similar way to green electricity: energy from both fossil and renewable sources is fed into the electricity grid. If the demand for green electricity increases, the expansion of renewable energies is driven forward, which are fed into the existing electricity grid.

The challenge with used tyres

Compared to other types of waste, the disposal and recycling of used tyres is a major challenge and a potential environmental problem. Tyres do not rot and consist of a large number of inseparable components and materials. This makes recycling very difficult. For this reason, used tyres have largely been mechanically downcycled into e.g. rubber granulate for floor coverings or thermally recycled in cement works to generate energy. Tyres that are not completely worn out are often exported outside Europe, where regulations for the safe disposal of used tyres are limited and used tyres are often simply incinerated. 4

However, the illegal disposal and storage of used tyres has also increased in Germany in recent years. This is due to the overall increasing volume of used tyres, higher costs of legal recycling and the lack of uniform legal regulations and responsibilities for proper disposal. The problem of illegal waste tyre mountains: Incorrect disposal (e.g. simple burning) and illegal dumping can release toxic substances into the soil and groundwater, leading to serious environmental and health damage. 5

Sustainability benefits: Ultramid® Ccycled® x SOLID products

By using Ultramid® Ccycled®, we are making a contribution to solving the problem of waste tyre disposal. This is because pyrolysis technology exploits the potential for a circular economy of used tyres by recovering recycled raw materials from used tyres and using them to produce high-quality textile fibres such as polyamide.

At pinqponq, we are always on the lookout for durable, high-quality materials that are produced in a resource-saving manner and utilise raw materials that have already been produced. Ultramid® Ccycled® has the same functional and aesthetic properties as conventional polyamide, but allows us to save fossil raw materials at the beginning of the value chain. In this way, we are helping to promote a circular economy for waste that was previously difficult to recycle, such as used tyres. In addition, the supply chain from used tyres to the end product is transparently traceable.

All Solid Styles

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel

-

Beispiel für ProdukttitelAnbieter:AnbieterNormaler Preis 19,99 €Normaler PreisGrundpreis pro

€Verkaufspreis 19,99 €Beispiel für Produkttitel